Your cart is currently empty!

Tag: Off-Grid

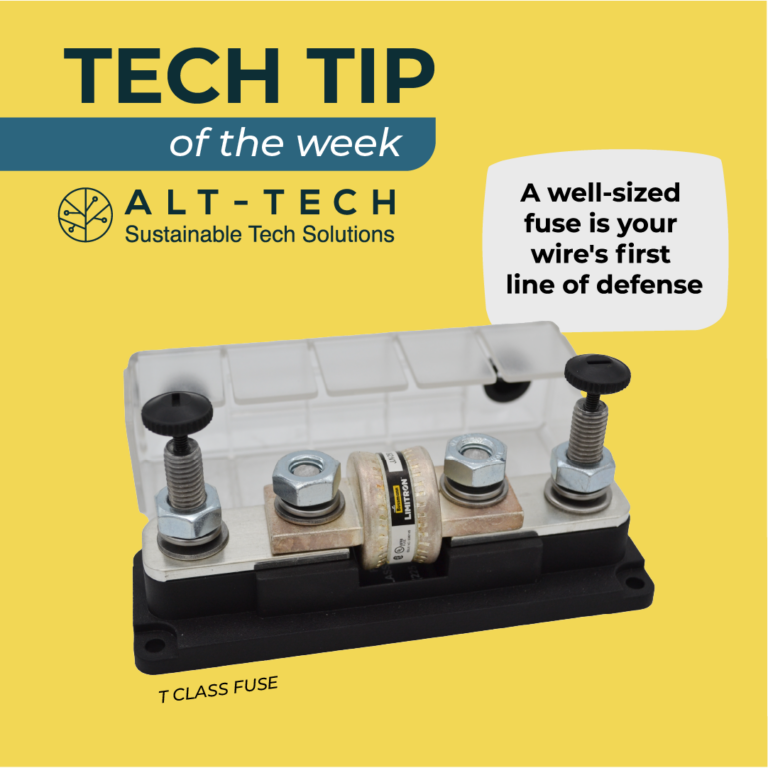

Fuses: Safeguarding your System Wiring

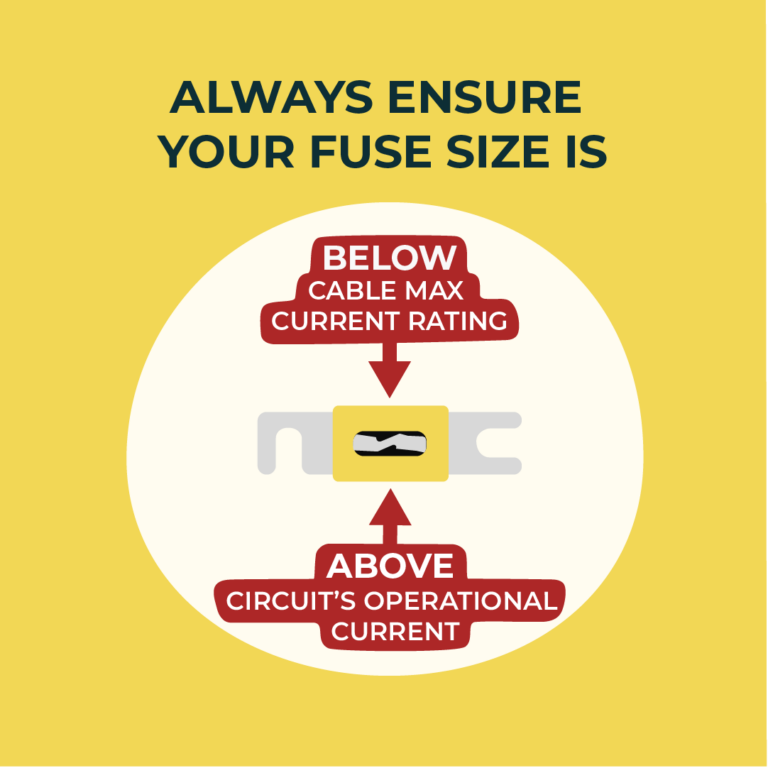

When calculating the fuse for your system, remember: The fuse’s primary role is to safeguard the wire’s integrity.

They shield against potential fire hazards by breaking the circuit if something goes wrong.

- Ensure your fuse size is above the circuit’s operational current and below the wire’s maximum current rating.

- Prioritize system safety by understanding that a well-sized fuse is your wire’s first line of defense.

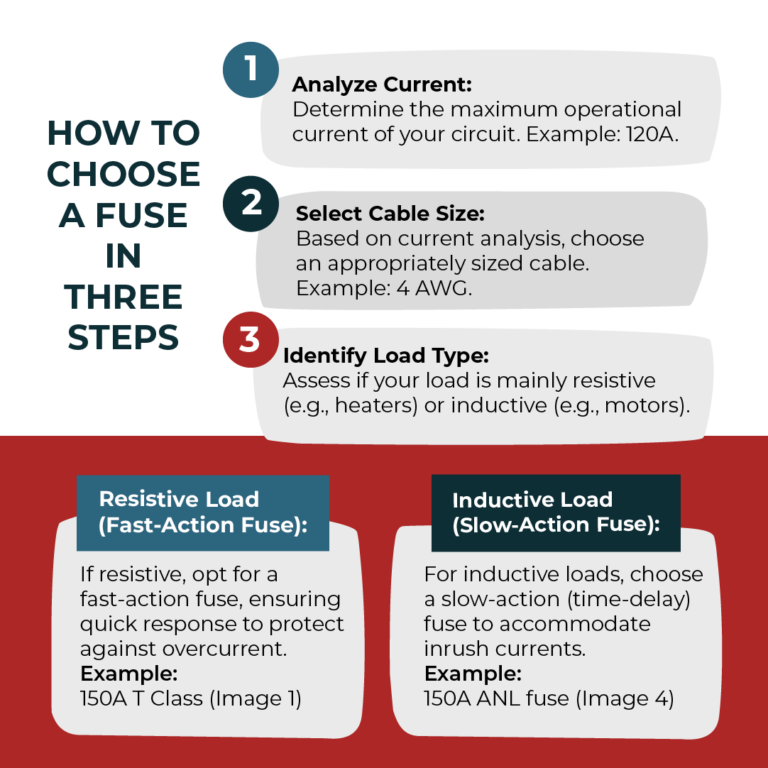

The following three steps will help you determine the best type and size of fuse for your system.

- Analyze Current: Determine the maximum operational current of your circuit. Example: 120A

- Select Cable Size: Based on current analysis, choose an appropriately sized cable. Example: 4 AWG.

- Identify Load Type: Assess if your load is mainly resistive (e.g., heaters) or inductive (e.g., motors).

Resistive Load (Fast-Action Fuse):If resistive, opt for a fast-action fuse, ensuring quick response to protect against overcurrent. Example: 150A fast-blow fuse.

Inductive Load (Slow-Action Fuse):For inductive loads, choose a slow-action (time-delay) fuse to accommodate inrush currents. Example: 150A time-delay fuse.

Check Manufacturer Recommendations when possible! If you need more advice our sales team are always happy to help.

Shop Fusing

Fusing

All your off-grid, DC electrical circuit protection needs are covered with ANL fuses, Blade fuses, FH type fuses and Victron megafuses, plus housing and holders.

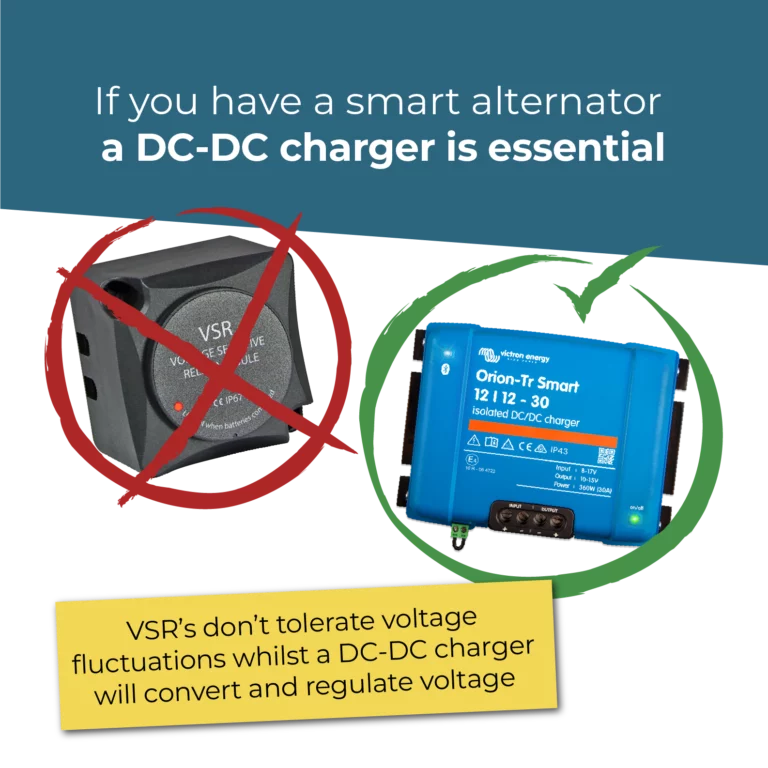

VSR’s & Smart Alternators

Smart alternators (prevalent in most vehicles made after 2006) provide efficient, variable voltage output, reducing emissions and enhancing battery charging. However, this voltage fluctuation doesn’t work well with traditional charging technology like VSR’s (Voltage Sensitive Relay’s).

The VSR’s depend on a constant voltage higher than 13.3V in most cases to be able to charge the auxiliary battery setup. A smart alternator in junction with the ECU of the car will decide when the starter battery is fully charged after cranking and dial the working voltage down after that, causing the VSR flick open and stoping the charging.If you have a smart alternator a DC-DC charger is essential.

These chargers efficiently convert and regulate their working voltage, ensuring your leisure battery receives the right charge, maintaining power on the road.

Shop DC-DC’s

DC to DC

Charge and maintain your batteries with DC to DC charging, our range includes convertors and isolated and non-isolated options from brands such as Victron and Enerdrive suitable for 12v, 24v or 48v.

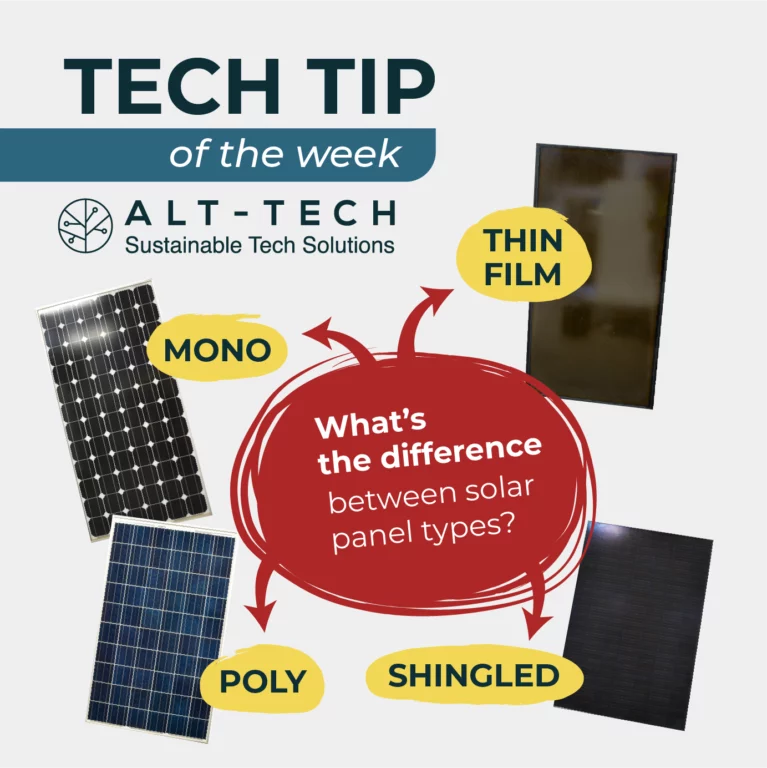

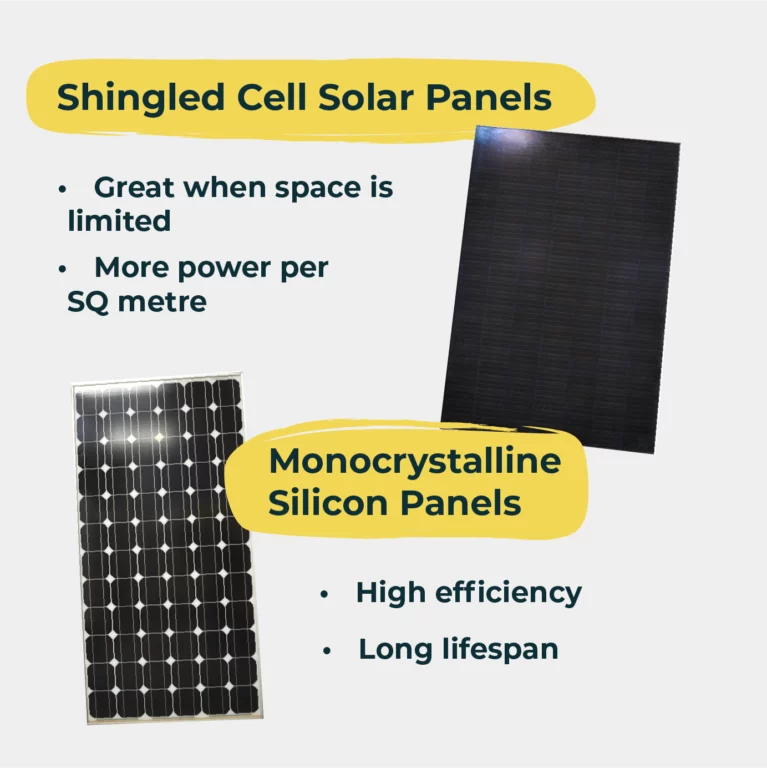

What’s the difference between solar panel types?

With a wide variety of solar panels available, understanding their differences and benefits will help you find the most suitable panel to meet your needs. The following four panel types are the most common varieties we stock at Alt-Tech.

Shingled Cell Solar Panels:

A Strip-over-strip design boosts power per SQ meter, no busbars and increased sunlight exposure. Reduced potential of micro-cracks.Use Case:

Limited space applications where generating the most power possible is imperative.Monocrystalline Silicon Panels:

A popular choice for decades, pure crystal cell formation results in slightly greater efficiency. Dark black appearance.Use Case:

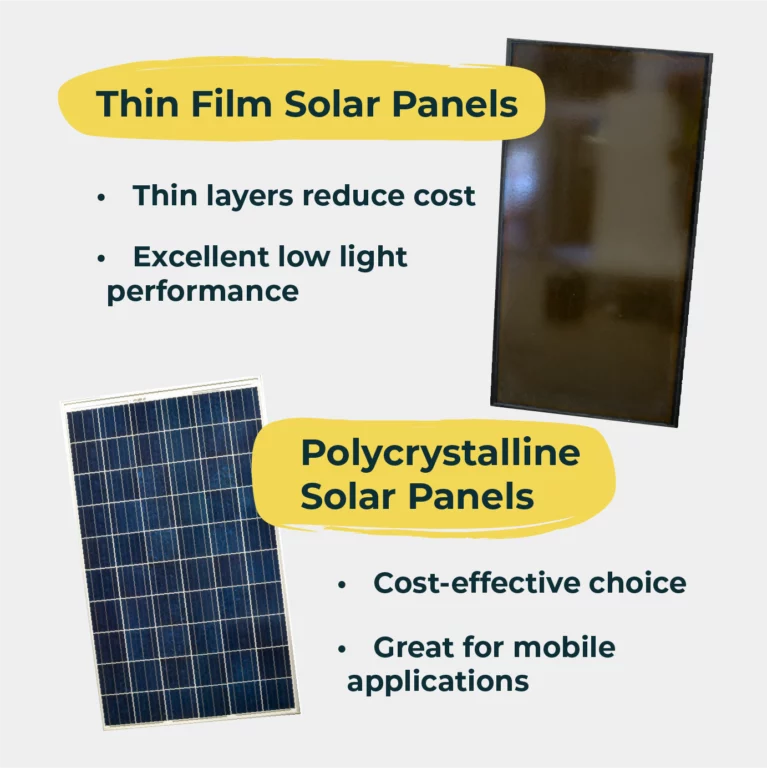

Residential and commercial applications.Polycrystalline Solar Panels:A cost-effective choice due to quicker production. Good for mobile applications as they are generally corrugation resistant.

Use Case: Common in residential installations.

Thin Film Solar Panels:Less efficient per SQ metre but excellent performance in low-light conditions. Thin film’s are less affected with temperature and shading.

Use Case: Low light sites with good amount of space to mount them.

Second-life panels are our preferred choice and we always have a range of thin film, poly and mono panels in stock. Only new shingled cell panels are available at present, due to being newer technology.

Our knowledgeable sales team are always ready to offer further advise on the best panels for your system.

Shop Solar Panels

Solar Panels

We stock a massive range of new and second life panels, assessed and covered by five year warranty, offering affordable, reliable options for your off-grid solar project.

Over 80% of the solar panels we retail are second-life or warehouse seconds. This means that availability of specific panels is unpredictable. Stock levels listed reflect real-time availability and if levels are lower than your requirements, your best option is to choose a different panel. It could be six months, a year, or we may never receive more of a particular panel.

For more information on second-life and warehouse second panels, please check our FAQ.

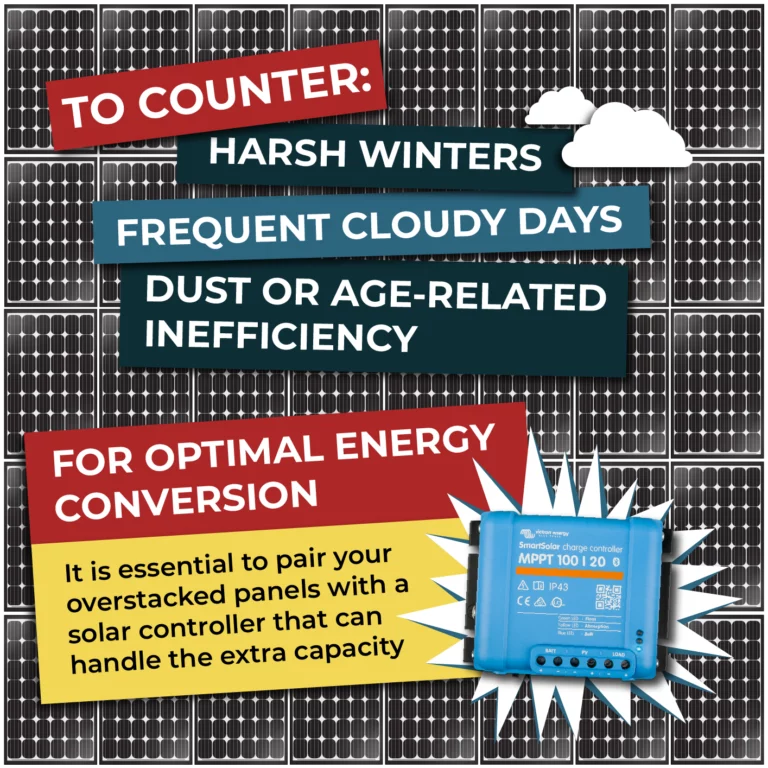

Why are Solar Panels Overstacked?

Over sizing your solar panel array in conjunction with the right solar controller is a strategic move that promises several advantages, especially to deal with harsh winters, frequent cloudy days, or panels that might face dust and age-related efficiency loss. Also, panels are rated using artificial light that’s 1000W/sqm at 25C, scenario that highly differs for real life use.

Here’s why this approach is a savvy choice:

Take, for instance, a Victron 100/20 MPPT controller. By connecting four 250W panels in a 2S2P configuration (~74V Voc & 18.5A Isc) to charge a 24V battery bank, you maintain constant energy input, yielding roughly a fairly constant 480W output. This means during the bulk of daylight hours you’ll produce a constant 20A (max output of MPPT).To make the most of oversizing, it’s crucial to pair your solar panels with an appropriate solar controller that can handle the extra capacity. This ensures optimal energy conversion and management.

Shop Solar

Solar

Our warehouse is full of solar PV panels, rail and mount to suit all kinds of off-grid applications from 4WD, camping & campervans to tiny homes, shacks, agricultural and rural properties. Over 80% of the solar panels we retail are second-life or warehouse seconds. We believe these high-performance products should fulfil their complete functional lifecycle. Panels arrive assessed and we provide a five-year warranty because we are confident in their capabilities.

These are the more sustainable and green option in alignment with our circular economic principles.Availability of specific 2nd life or warehouse seconds panels is unpredictable. Stock levels listed reflect real-time availability and if levels are lower than your requirements, your best option is to choose a different panel. It could be six months, a year, or we may never receive more of a particular panel.

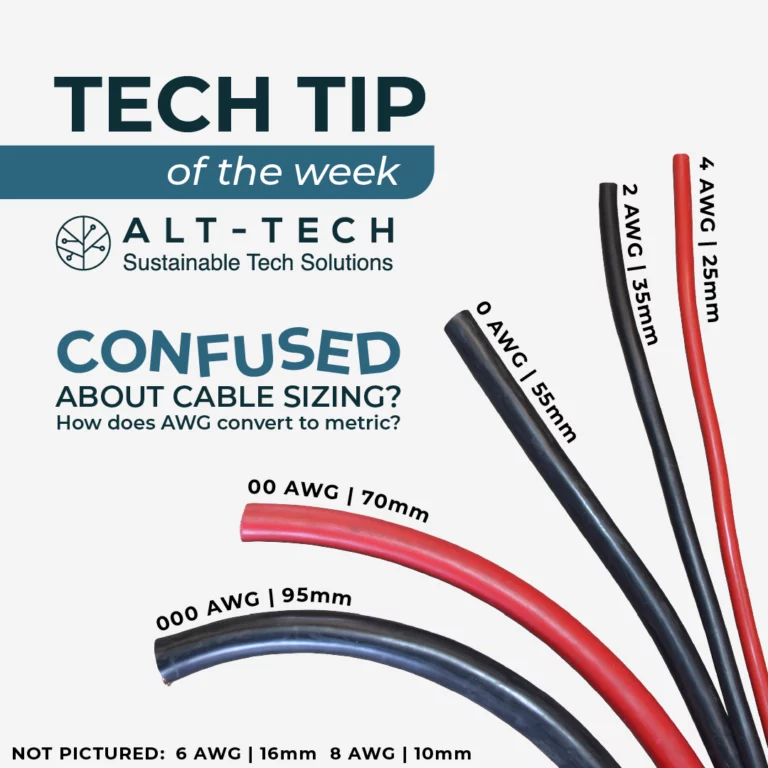

Confused about Cable Sizing?

Confused about cable sizing?

Wondering how AWG converts to metric measurement?The AWG system provides a standardised way to measure wire thickness and is widely used in North America whilst the metric system provides a more straightforward and universally recognised way to measure wire thickness.

In the automotive industry, electrical cables are often labeled using MM standard to denote their size. For instance, you might encounter cables labeled as 2.5mm, 3mm, 4mm, 5mm, or 6mm. However, it’s crucial to note that these measurements don’t directly correspond to the cable’s nominal conductor area in square millimetres (mm²).

Sometimes it can be challenging to get AWG gauged cable to fit in metric lugs. A handy tip is to use electrical tape to compress the wire strands, slide the lug on the end and slowly pull off the tape.Just remember, choosing the right cable size is like finding the perfect pair of shoes – if they don’t fit, you’re in for some uncomfortable dancing, and in our case, a potential electrical meltdown.

Shop Cable

Cable

Our cable wall is stocked with a range of DC, battery, solar and earth cabling for 12v, 24v and 48v off-grid systems so you can purchase all components for your solar power project in one place. Accessories include heat shrink, conduit, lugs and more.

Standard Lugs VS Narrow Palm Lugs

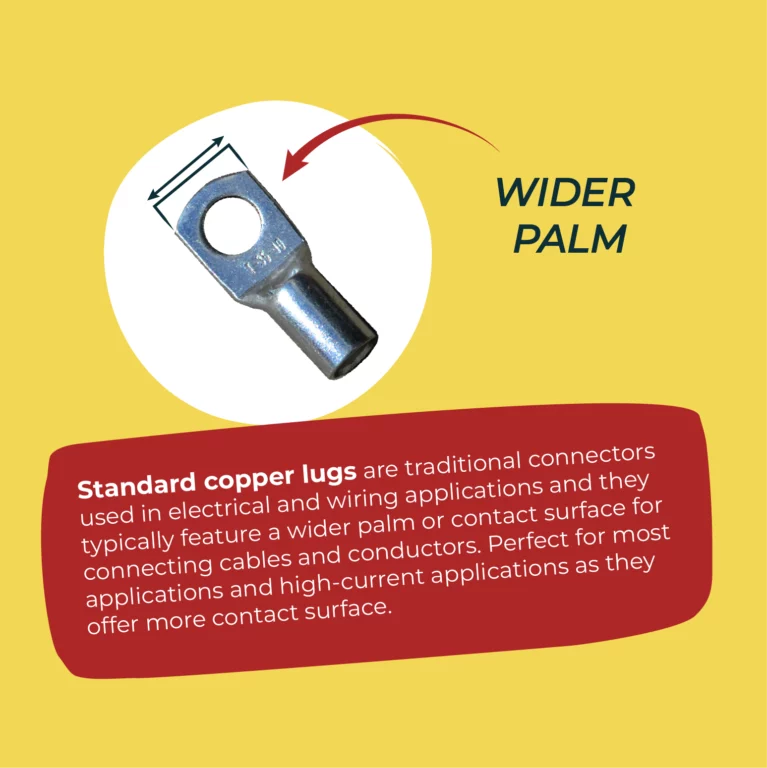

Standard copper lugs are traditional connectors used in electrical and wiring applications; they typically feature a wider palm or contact surface for connecting cables and conductors. Perfect for most applications and high-current applications as they offer more contact surface.

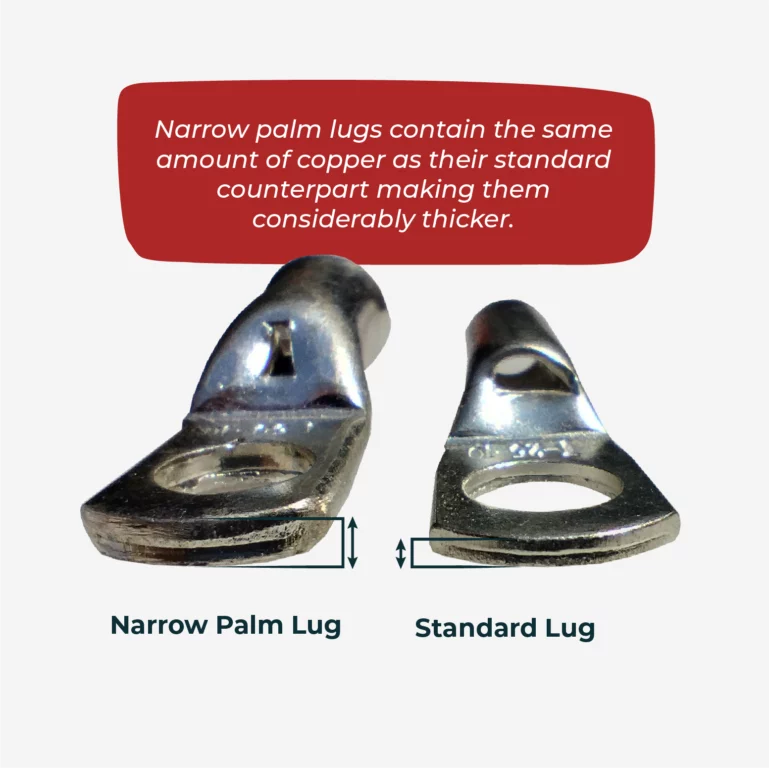

Narrow palm copper lugs are a specialized type of lug connector with a narrower contact surface compared to standard lugs. This design is specifically tailored to certain applications. Awesome for space constrained applications, providing a secure and precise connection maintaining excellent copper conductivity.

When choosing between lugs it’s essential to consider the specific requirements of your project. Standard copper lugs offer versatility and high current-carrying capabilities, making them suitable for a wide range of applications.

On the other hand, narrow palm copper lugs are ideal when space is limited, ensuring a secure and precise fit.

Which Charge Controller Should You Choose?

Which solar charge controller should you choose?

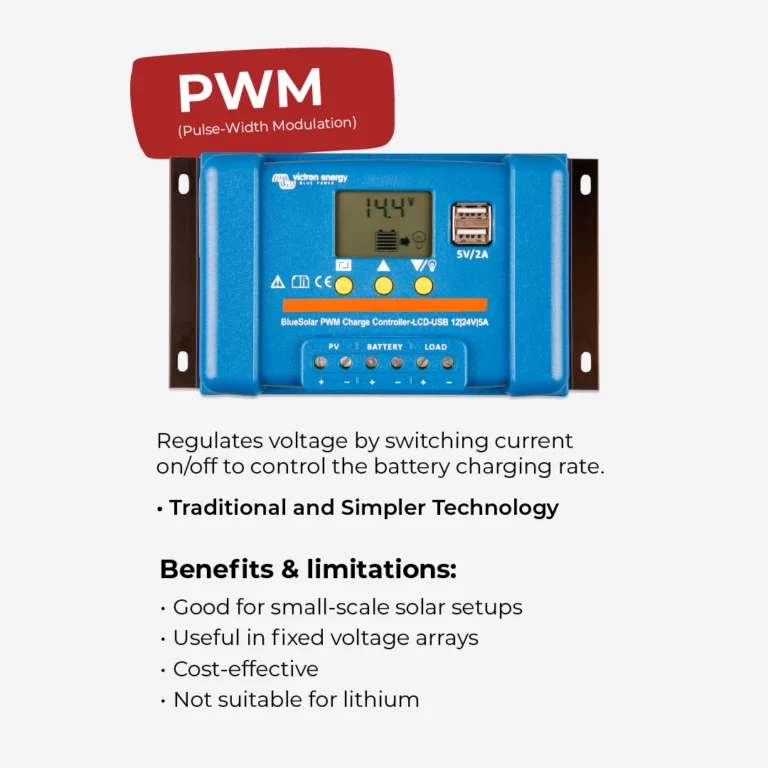

PWM (Pulse-Width Modulation) solar charge controllers are a traditional and simpler technology. They regulate the voltage from the solar panels to the battery by rapidly switching the connection on and off, controlling the battery’s charging rate. Awesome for small-scale solar setups and fixed voltage arrays (panel votlage close to battery). Cost-effective solution but not suitable to charge lithium batteries.

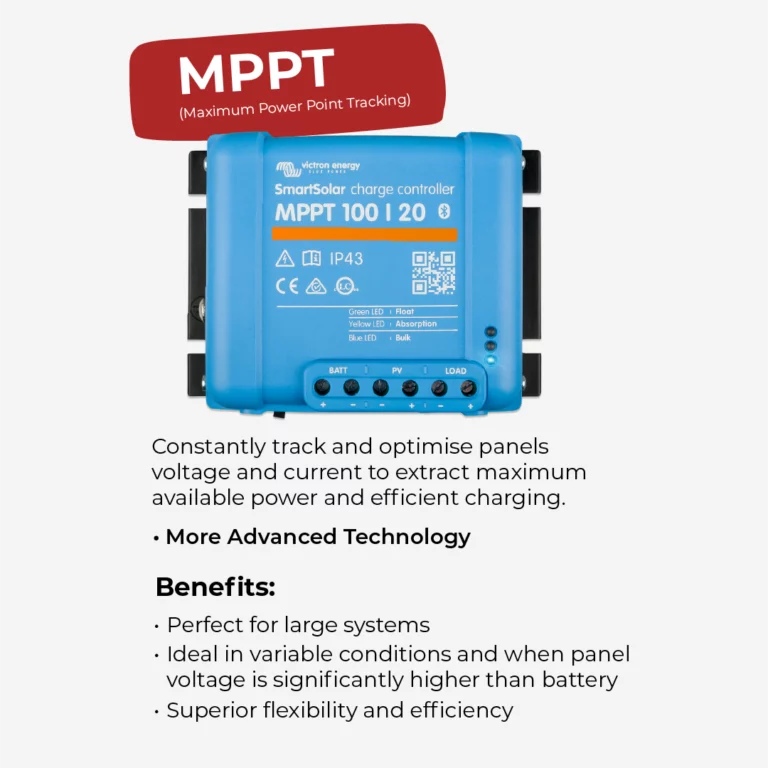

MPPT (Maximum Power Point Tracking) solar charge controllers are more advanced. They constantly track and optimize the solar panel’s voltage and current to extract the maximum available power and efficiently charge the battery. Perfect for larger systems, variable conditions and panel strings with significantly higher than voltage the battery.

The choice between PWM and MPPT solar charge controllers largely depends on the specific requirements of your solar power system. If you have a small, simple setup with fixed voltage solar panels, a PWM controller can provide a cost-effective solution. However, for larger systems with varying conditions and high-voltage panels, an MPPT controller offers superior efficiency and flexibility.

Shop Solar Controllers

Regulators

MPPT and PWM charge controllers for regulating amperage and voltage on solar systems including brands such as Victron bluesolar and smartsolar, Epever and Amptron.

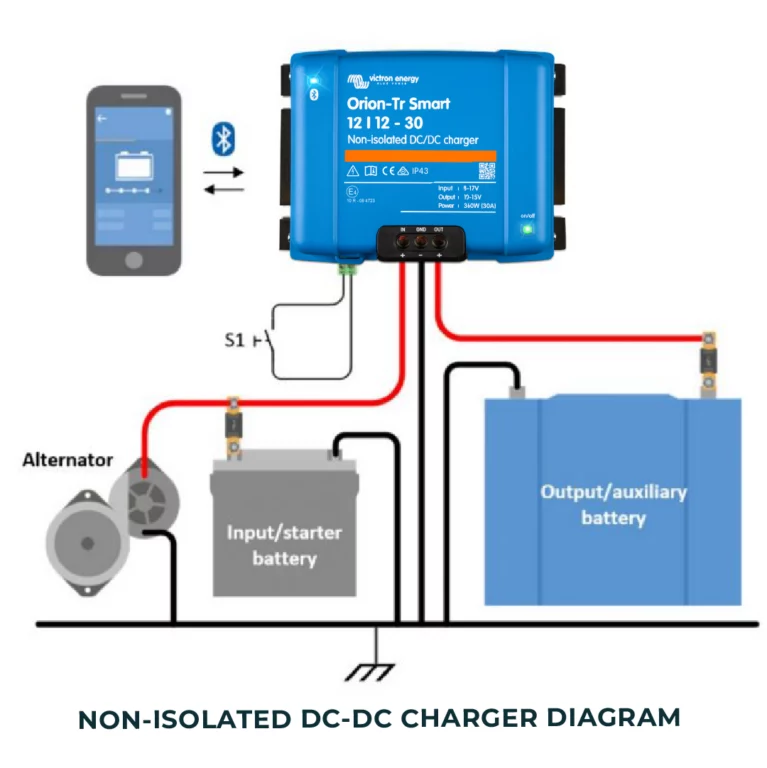

Isolated VS Non-Isolated DC-DC Chargers

For this weeks Tech Tip we’re comparing isolated and non-isolated chargers, which one meets your needs?

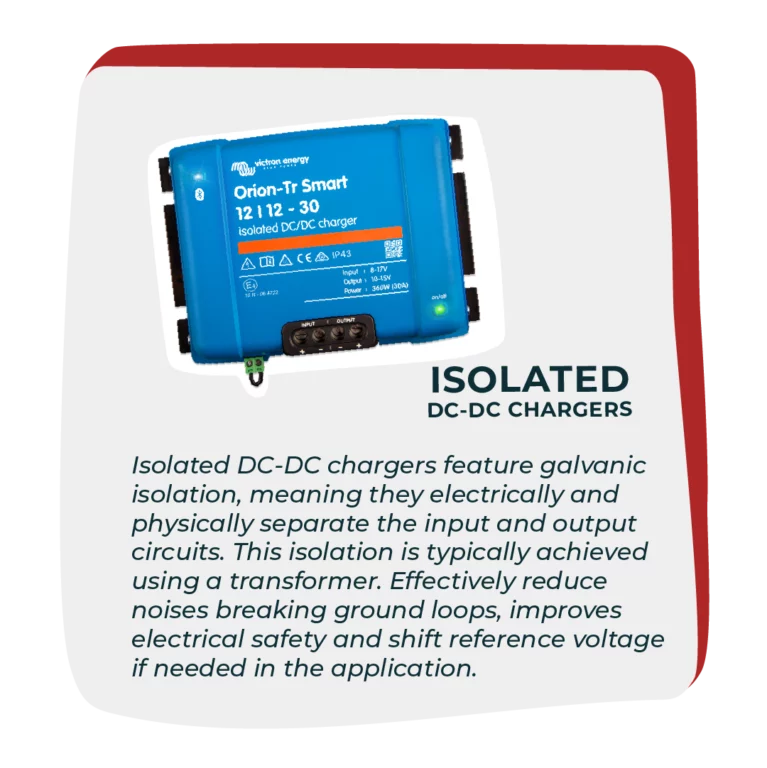

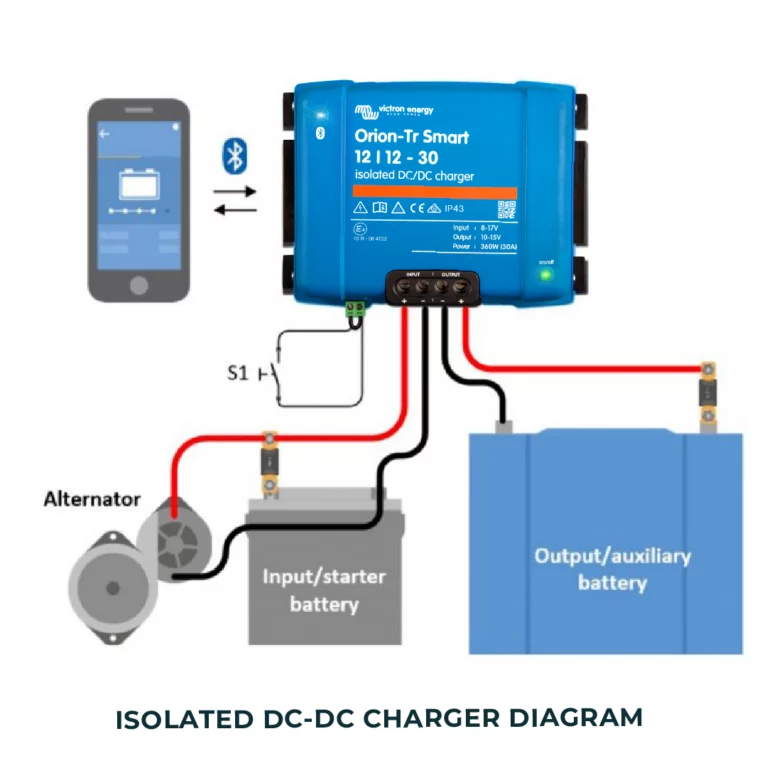

Isolated DC-DC chargers feature galvanic isolation, meaning they electrically and physically separate the input and output circuits. This isolation is typically achieved using a transformer. Effectively reduce noises breaking ground loops, improves electrical safety and shift reference voltage if needed in the application.

Non-isolated DC-DC chargers lack galvanic isolation, and they share a common ground connection (negative) between the input and output voltages. Higher efficiency and are a more cost-effective solution.

How to choose

Choosing between isolated and non-isolated DC-DC chargers depends on your specific project requirements. If safety, ground loop isolation, or reference voltage shifting is critical, isolated chargers are the way to go. On the other hand, if cost savings, space constraints, or energy efficiency are your primary concerns, non-isolated chargers offer a practical solution.Shop DC-DC

DC to DC

Charge and maintain your batteries with DC to DC charging, our range includes convertors and isolated and non-isolated options from brands such as Victron and Enerdrive suitable for 12v, 24v or 48v.

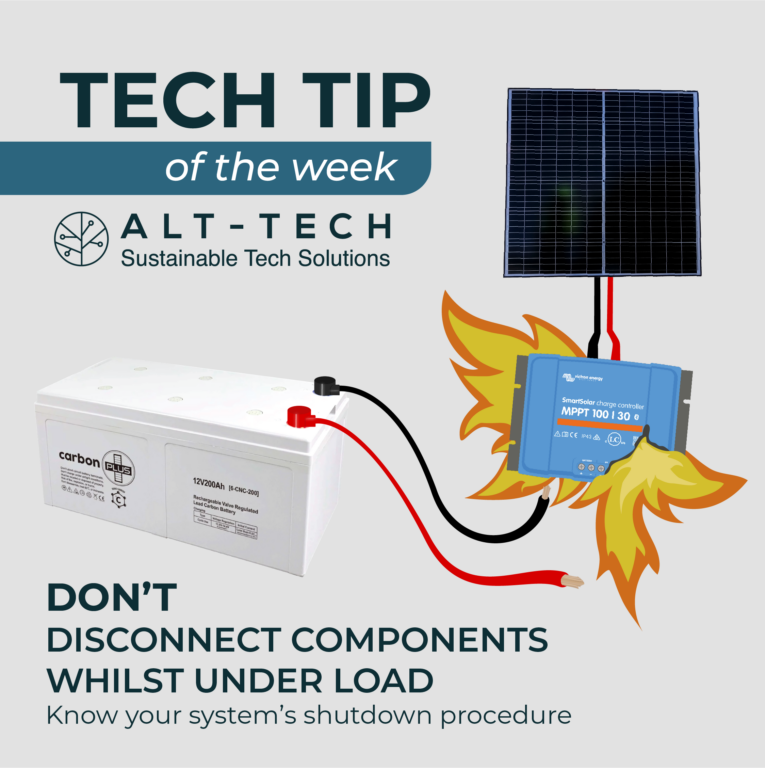

Disconnecting Components

Disconnecting the battery, or any device under load, can cause voltage spikes and fluctuations which may damage the inverter, charge controller, and other sensitive electronics connected to the system, leading to costly repairs, replacements and voided warranty.

To avoid these issues, it’s generally advisable to follow proper shutdown procedures for your off-grid setup, including turning off or disconnecting appliances and systems before disconnecting the battery.

Decoding Battery Technologies: AGM, Lead-Carbon, and LiFePO4 Batteries

In our rapidly evolving world, energy storage is a critical component of various industries, from powering electric vehicles to ensuring uninterrupted energy supply in remote locations. Among the diverse battery technologies available, three noteworthy contenders are Absorbent Glass Mat (AGM) batteries, Lead-Carbon batteries, and Lithium Iron Phosphate (LiFePO4) batteries.

This article delves into the unique characteristics, applications, and advantages of each technology, helping you make informed decisions about which battery type suits your specific needs.

AGM Batteries: A Dependable Classic

AGM batteries have long been a reliable choice for various applications, from uninterruptible power supplies (UPS) to marine and recreational vehicles. They utilize a glass mat separator, which is saturated with electrolyte to ensure minimal maintenance requirements and a spill-proof design. AGM batteries are known for their:

- Deep Cycling Abilities: AGM batteries can withstand deep discharge cycles without significant performance degradation, making them suitable for applications requiring frequent charging and discharging.

- Vibration Resistance: Their construction offers enhanced durability against vibrations, making them ideal for mobile applications like RVs and boats.

- Maintenance-Free Operation: Sealed design eliminates the need to add water or electrolyte, reducing maintenance efforts.

Lead-Carbon Batteries: Merging Tradition with Innovation

Lead-Carbon batteries combine the strengths of traditional lead-acid batteries with advanced carbon technology. This hybrid approach brings several advantages, making them a preferred choice for applications such as renewable energy storage and telecom backup systems. Key features of Lead-Carbon batteries include:

- Enhanced Cycle Life: Incorporating carbon technology extends battery life and improves cycle performance compared to standard lead-acid batteries.

- Fast Charging: Lead-Carbon batteries can accept higher charging currents, reducing the time required for recharging.

- Partial State of Charge Tolerance: Lead-Carbon batteries can operate efficiently even at partial states of charge, minimizing the risk of sulfation.

LiFePO4 Batteries: Pioneering Energy Density and Longevity

Lithium Iron Phosphate (LiFePO4) batteries have taken the energy storage market by storm, offering high energy density, exceptional cycle life, and lightweight construction. These batteries have become the go-to choice for electric vehicles, renewable energy systems, and portable electronics. Key advantages of LiFePO4 batteries include:

- High Energy Density: LiFePO4 batteries offer a high energy-to-weight ratio, allowing for more compact and lightweight designs.

- Extended Cycle Life: With thousands of charge-discharge cycles, LiFePO4 batteries outlast many other battery types, contributing to lower long-term costs.

- Safety: LiFePO4 chemistry is inherently stable, reducing the risk of thermal runaway and fire incidents associated with some other lithium-ion chemistries.

Choosing the Right Battery for Your Needs: Use Cases, Pros and Cons

AGM

Use Cases

- Recreational Vehicles: Their durability and resistance to vibrations make them suitable for powering RVs and boats.

- Backup Power: AGM batteries serve as backup power sources for critical systems like data centers and medical equipment.

Pros

- Maintenance-Free: Sealed design eliminates the need for regular maintenance and water additions.

- Deep Cycling: AGM batteries handle deep discharge cycles well, making them suitable for applications requiring frequent cycling.

- Vibration Resistance: Ideal for mobile applications due to their ability to withstand vibrations.

Cons

- Limited Energy Density: AGM batteries have lower energy density compared to some other technologies.

- Sensitive to Overcharging: Overcharging can lead to reduced battery life and potential damage.

Lead-Carbon

Use Cases

- Renewable Energy Storage: Lead-Carbon batteries are used to store energy generated by solar panels and wind turbines.

- Telecom Backup: Their fast charging and partial state of charge tolerance make them valuable for backup power in telecom systems.

Pros

- Enhanced Cycle Life: Combining lead-acid and carbon technology results in longer battery life and improved cycle performance.

- Fast Charging: Lead-Carbon batteries accept high charging currents, reducing downtime.

- Partial State of Charge Tolerance: Can operate efficiently even at partial charge levels.

Cons

- Moderate Energy Density: Lead-Carbon batteries have lower energy density compared to lithium-ion technologies.

- Weight: They tend to be heavier than some other battery types.

LiFePO4

Use Cases

- Electric Vehicles: LiFePO4 batteries power electric cars due to their high energy density and long cycle life.

- Renewable Energy Systems: They store energy from solar and wind sources for later use.

- Portable Electronics: LiFePO4 batteries are used in laptops, smartphones, and other portable devices.

Pros

- High Energy Density: LiFePO4 batteries offer excellent energy-to-weight ratio.

- Long Cycle Life: Thousands of charge-discharge cycles before significant capacity degradation.

- Safety: Stable chemistry reduces the risk of thermal runaway and fire incidents.

Cons

- Higher Cost: LiFePO4 batteries can be more expensive upfront compared to other battery types.

- Limited Voltage Range: Voltage per cell is lower than some other lithium-ion technologies, requiring more cells for certain applications.

Tailoring Your Choice to Your Needs

Selecting the appropriate battery technology involves understanding the unique benefits and limitations of AGM, Lead-Carbon, and LiFePO4 batteries. AGM batteries offer reliability and deep cycling for applications requiring constant charge-discharge cycles. Lead-Carbon batteries blend tradition with innovation, excelling in renewable energy storage and backup power scenarios. LiFePO4 batteries lead in energy density and longevity, making them ideal for electric vehicles and energy-intensive applications. By assessing your specific requirements against these technologies’ strengths and weaknesses, you can make an informed decision that aligns with your goals for efficiency, reliability, and sustainability.