Your cart is currently empty!

Tag: Batteries

Balancers

When putting batteries in series for a 24V or 48V system it is a good idea to use a balancer. This balancer ensures that the voltages of all the batteries in the pack remain equal and balanced. Without a balancer, especially on lithium systems, the voltage of each of the 12V batteries can drift apart over time. Balancers help to minimise this effect and keep equal voltages across batteries.

The balancers we are talking about here are different to the balancers we use on lithium cells. These balancers balance between 12V batteries, not 3v cells.

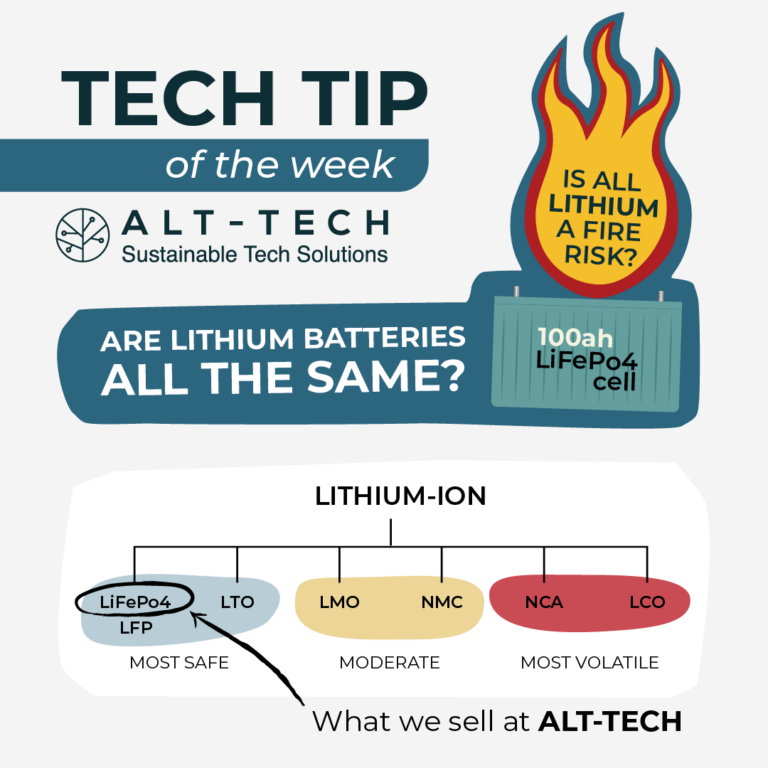

Lithium Safety

At Alt-Tech we sell lithium iron phosphate (also called LiFePO4 or LFP) batteries.

These are just one of the various types of lithium-ion batteries that are available currently. Many people are aware of the risk of fire that lithium batteries pose, however, it is important to recognise the differences between the different chemistries. Lithium iron phosphate is a very safe, low fire risk, type of lithium. It does not present as much risk as some of the types of lithium batteries you often hear about.

GWL Group, a European battery manufacturer created an excellent video which demonstrates the risk posed by different lithium types.

Paralleling Lithium Batteries

Many people want to run multiple lithium batteries in their system to increase their battery storage. This makes sense, sometime one battery just doesn’t provide the runtime you need. To run multiple batteries in a single system, without increasing the system voltage, you will be looking at paralleling batteries.

What is paralleling?

Image 1: Batteries in parallel When we talk about parallel batteries we are talking about what we see in image 1. Paralleling is a method of wiring batteries that increases capacity while keeping battery voltage constant.

What is in a lithium battery?

Another important thing to remember is that lithium batteries have BMSs (battery management system). The BMS protects the pack from fault conditions commonly, over-voltage, under-voltage, temperature, and sometime over-current. When a fault condition detected, the BMS switches of the battery.

Why is paralleling risky?

1. May void your warranty

Some lithium battery manufacturers specify that their batteries cannot be paralleled. If you decide to not follow their specifications, you will void your warranty. Some other manufacturers specify certain conditions on parallel use. These conditions may specify the maximum amount of batteries allowed in parallel, the maximum charge and discharge currents for parallel use, and more.

2. BMS damage, especially on high current

One of the reasons that paralleling is risky is because of the limitations of the BMSs inside the lithium batteries. An example will explain this concept best.

Example. Lets assume you have the following system:

– 2x 100Ah lithium batteries. 100A max discharge, 50A max charge.

– 12v 2000W inverter. We will assume that this is being used to its full capacity.

As can be seen in (image 2) when the inverter is running at full capacity, the batteries are both working together to supply 167A. Assuming the batteries both contribute half of this current, they will each supply approximately 83A (It is important to note that is unlikely that each battery will supply exactly half the required current). In the event that one of the batteries BMS trips (switches off), then suddenly one battery is left trying to supply the full load on its own. This means that one single 100A rated battery is trying to supply a load of 167A. This will very likely destroy the battery that is still on.

It is difficult to guarantee how much of the load or charge current each battery will contribute to. If the total load exceeds the ratings of a single battery, you are risking damaging your batteries.

Image 2: Batteries in parallel supplying 167A to inverter If you were to parallel, how might you do it well?

Image 3: Pylontech RT12100G31 battery 1. Use batteries designed to be used in parallel

Using batteries such as the Pylontech RT12100G31 is an excellent choice if you want to parallel batteries correctly. These batteries have built in communications that allow batteries to “talk” to each other. This communication prevents damage caused by parallel use and is a very reliable method of paralleling lithium batteries. This method of paralleling using communication allows the battery current ratings to “add up” when paralleled.

2. Check your manufacturer warranty

If you plan on paralleling your lithium batteries check to make sure you aren’t voiding your warranty. Look through the specifications carefully. Some manufacturers limit the charge/discharge current when the batteries are used in parallel.

Image 4: Illustrating balanced wiring and fusing 3. Balanced wiring

It is important to ensure that the load/charge is evenly shared between paralleled batteries. This means that the cable run to each battery should be equal. This can be done in a few ways as show in the image 4. The goal of the wiring is to ensure that voltage drop is shared evenly across batteries.

4. Low current (below single battery limit)

Running low current devices of parallel lithium batteries can be a safe option. Keeping the load/charge currents below the rating of a single battery minimises the risk that you will damage a battery due to over-current. Running a fridge, for example, off parallel lithium batteries can be a good way to increase runtime.

5. Charge batteries evenly first

Before connecting lithium batteries in parallel, charge them evenly. Putting each battery on a quality charger and allowing them to fully charge is good practice. Evenly charging the batteries reduces the risk of high current flowing between batteries due to different charge levels.

6. Fusing

Fusing each battery can be a good step to improve the safety of your battery setup. Fusing each battery ensures that no battery will exceed its maximum current rating. This can help to reduce some of the risks of parallel batteries. Note, however, that if a BMS trips and causes high current on a battery, the fuses of the batteries will blow. Fusing is not a recommended method of getting around current limits, simply a backup protection to improve battery safety.

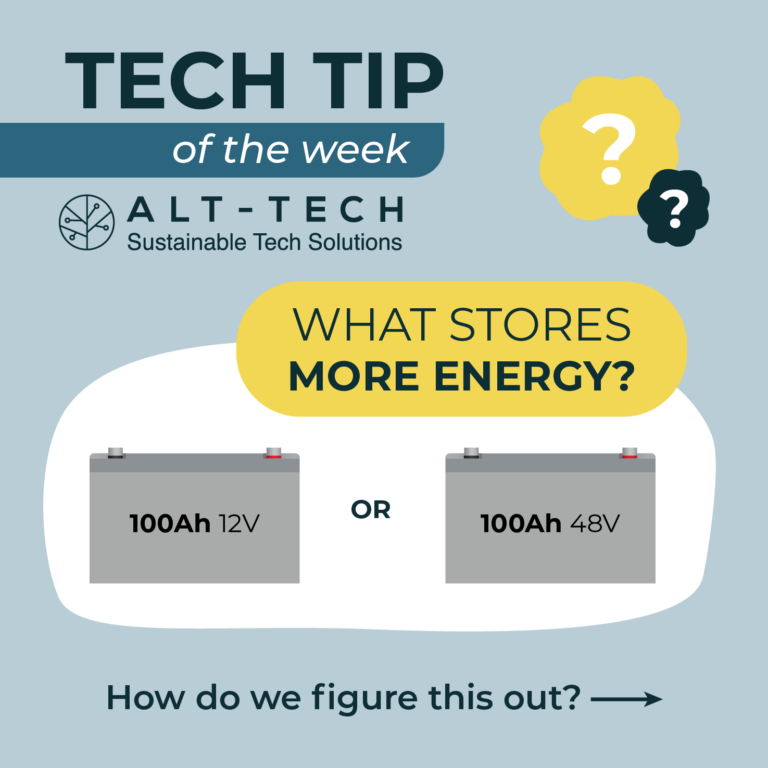

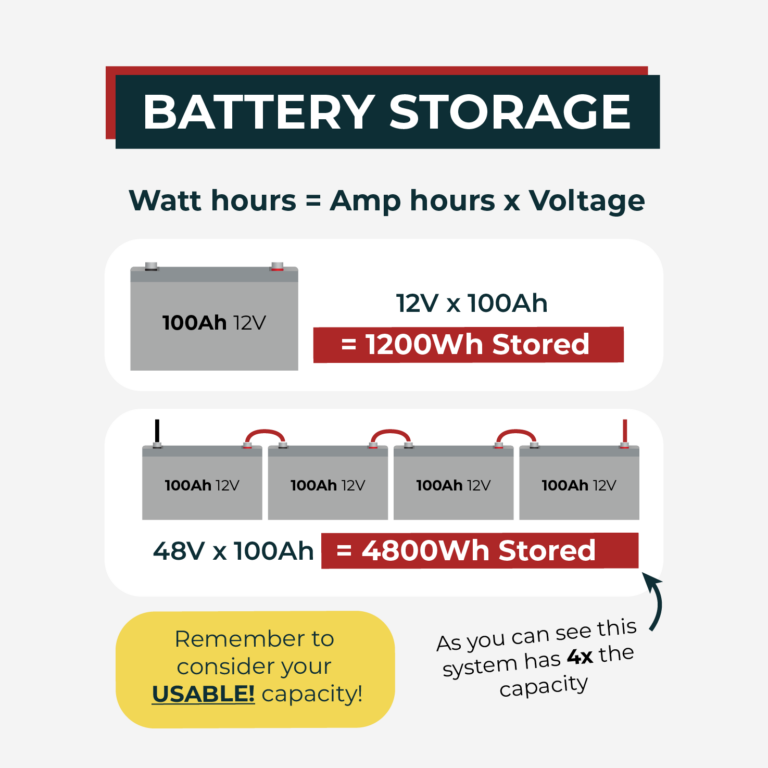

Calculating Watt-hours

Imagine you have a 100Ah 12v battery and a 100Ah 48V battery, which one stores more energy?

The 48V 100Ah battery stores 4x the power of the 12V 100Ah battery. How is this possible? Don’t they have the same 100Ah capacity?

Yes they have the same Amp-Hour rating, however, Amp-Hours are not the full story. In fact, amp hours are, in our opinion, not a very useful measure of a battery’s capacity. Watt hours are a far more useful measure of battery capacity.

Watt hours are similar to Amp-Hours in that they measure the storage of a battery. However, Watt hours are independant of the voltage of the battery. So where Amp-Hours measure how many amps can be supplied over time, watt hours measure how many watts can be supplied over time.

A 100Ah battery as we know will supply 1A for 100h.

A 100Wh battery will supply 1W of power for 100h.See how Watt-Hours are much more useful for determining how long you can run a certain wattage load. It is easy to see how a 100Wh battery can supply a 100W load for 1 hour. Watt-Hours remove the confusion assosciated with battery voltage and Amp-Hours.

There are two useful ways of calculating watt hours.

This first equation is useful for calculating the Watt-Hour storage of a battery:Watt-Hours (Wh) = Battery Capacity in Amp-Hours (Ah) x Battery voltage (V)

Example:

100Ah x 12V = 1200Wh of energy stored

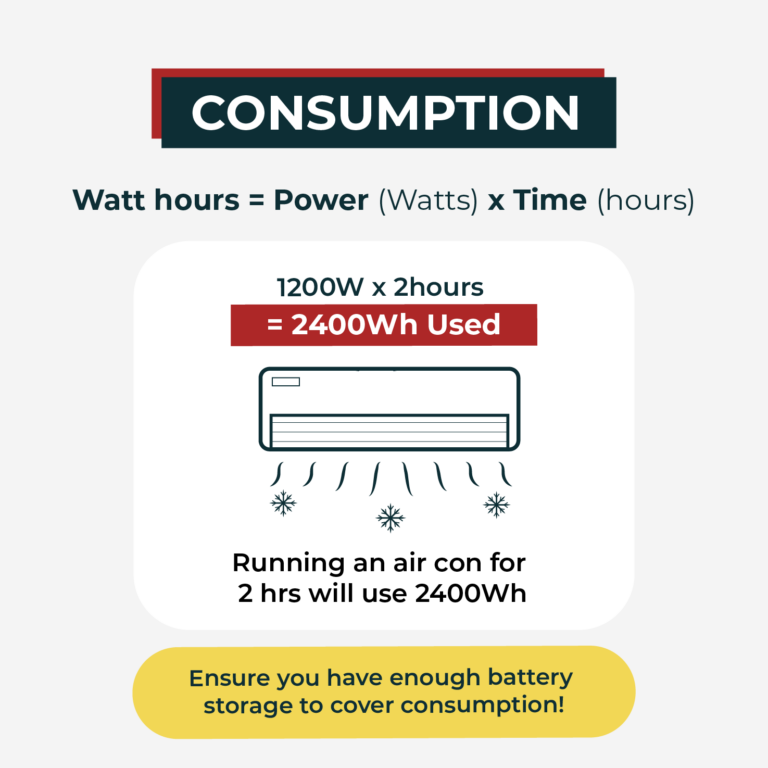

100Ah x 48V = 4800Wh of energy storedThis second equation is useful for measuring how many Watt-Hours a device might use over time:

Watt-Hours (Wh) = Power in Watts (W) x Time in Hours (H)

Example:

Running a 1000W load for 6 hours. How many Watt-Hours would that use.

1000W x 6 hours = 6000Wh or 6kWh

Can I Run My Lithium Battery With No BMS?

Our immediate answer is NO, ABSOLUTELY NO.

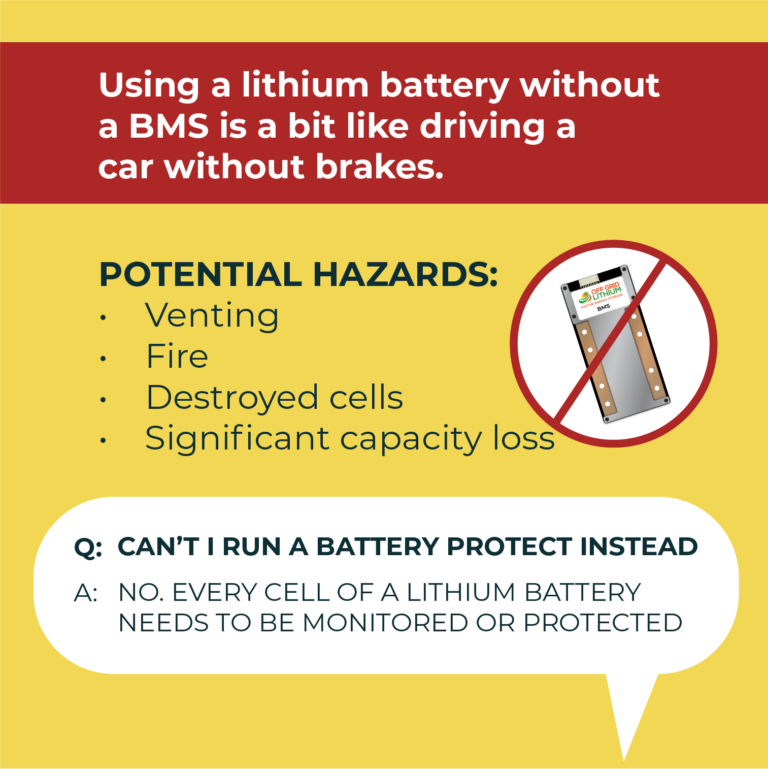

But lets have a look at that a bit more…Technically speaking, yes lithium batteries will output power even without a BMS. However, it is unsafe to do so. The BMS is a protection circuit. It protects the batteries from over-voltage, under-voltage, and sometimes also over-current and over temperature.

Running a lithium battery without a BMS is a safety hazard. Even if the batteries don’t vent or catch fire, the batteries will almost certainly be damaged and swell if discharged too much. Overdischarging or overcharging is a common way that a lithium battery can be damaged when not using a BMS. Running the battery even slightly too flat will severely reduce the capacity of the batteries.

So you may say why can’t I run a battery protect to protect my lithum battery? That is unfortunately not good enough for lithium. Every cell of a lithium battery needs to be monitored and protected. If even one cell goes over-voltage or under-voltage you will permanently damage the battery pack.

Using a lithium battery without a BMS is a bit like having a car without brakes. Sure the car drives just fine without them, however, it is an inevitable safety hazard.

So while yes, technically you can run your lithium battery without a BMS, for the relatively low cost of a BMS is it worth damaging thousands of dollars worth of lithium cells or worse?

Temperature Compensation

Temperature compensation is a feature of some high quality battery charging devices. It is a setting that allows the charger to adjust the charging voltage of the battery to suit the temperature of the battery. Most battery datasheets specify that the battery charge voltage should be reduced at high temperatures to prolong the battery lifespan.

Correctly setting the temperature compensation of your charger may improve the lifespan of your battery bank. The correct compensation value for your batteries should be available in the battery datasheet or from the battery supplier.

The value you are looking for is something such as -16.20mV/C (Victron Default).

Troubleshooting Lithium

Lithium battery technology has evolved and LiFePo4 batteries provide a safer option compared to other types of lithium battery. Lithium excels in mobile and space-restricted applications where temperature can be controlled and has become an increasingly popular choice. This edition we tackle troubleshooting different lithium battery options; both prebuilt and DIY.

Introduction to Lithium Batteries

Lithium batteries are made up of a set of cells, a BMS (battery management system), and a balancer. Lithium batteries always require protection circuitry (a BMS) to protect them. For prebuilt batteries, the BMS and balancer are built inside the battery. Lithium cells are sensitive to over-voltage, under-voltage, temperature, and high currents. It is the BMS’ job to protects the cells from these damaging conditions.

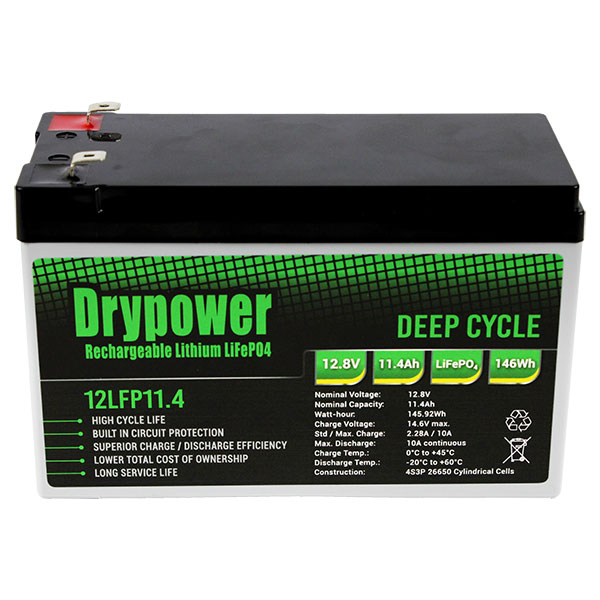

Drypower pre-built lithium battery alongside a variety of lithium cells What might cause lithium batteries to fail?

There are many reasons why a lithium battery may not be working as expected. Some of these common problems for lithium batteries are outlined in this guide.

Troubleshooting | Universal Issues

Applies to most lithium batteries whether DIY or Prebuilt

Charge settings incorrect:

It is important when charging lithium batteries to always use a lithium compatible charger with the correct charge profile selected. This will ensure that the battery charges to the correct voltages without tripping the BMS protection circuit.

Tripped BMS – battery too flat:

If your lithium battery has been discharged to fully flat, the BMS will switch the battery off to protect the battery. This protection is good because it saves your battery from damage.

Symptoms:

Low battery voltage (often around or below 10V for a 12V battery)

Battery not charging

- Battery not running any loads

Fix:

Switch off all battery loads. Connect a charger as soon as possible. You risk the battery never turning back on if you leave the battery fully flat for an extended period of time. If the charger does not charge the battery see the relevant section on resetting a tripped BMS.

Switch off all battery loads. Connect a charger as soon as possible. You risk the battery never turning back on if you leave the battery fully flat for an extended period of time. If the charger does not charge the battery see the relevant section on resetting a tripped BMS.

Tripped BMS – battery too full:

Symptoms:

Battery not accepting current when full

Battery switching off when almost full while charging

Chargers moving into absorption mode too early

Fix:

Check your charger settings are correct. If you have selected the wrong charge profile, this is a likely cause of a BMS tripping while charging.

It is possible that if the battery cells are out of balance, that you will see the BMS tripping while charging. Please refer to the relevant section to troubleshoot unbalanced cells.

Low capacity – battery not running for as long as it should:

Symptoms:

Battery not running loads for as long as expected

Battery capacity measuring significantly less than expected

Fix:

Check that the cells are balanced, see the relevant section for balancing instructions

Be sure that you are measuring capacity correctly. If you have a shunt, make sure its settings are correct. See the relevant section for instructions.

If your battery is old or heavily used, it may be a sign that the cells are losing capacity

Shunt settings incorrect:

Symptoms:

Battery percentage shown on the shunt is inaccurate

Fix:

Follow the instructions for your shunt to set the correct settings. If you have a Victron shunt purchased from Alt-Tech, please refer to the settings sheet you should have received.

Parallel batteries – damaged BMS:

Paralleling lithium batteries can be risky.

Many prebuilt lithium batteries cannot be placed in parallel without risking damage and voiding their warranty. Be sure to check if your battery manufacturer will warranty parallel batteries, and what conditions they impose on their parallel use.

When making DIY kits, paralleling BMSs is not advised. If parallel BMSs are required the system design should be approached with caution.

When two lithium batteries are paralleled you have two BMS’ working together. This can be ok until one of them trips (switches off). When one BMS switches off it leaves the other BMS to do all the work. If you are drawing 150A and one of your 100A rated BMSs switches off because the battery is flat, you will almost certainly damage the remaining BMS.

You CAN NOT rely on BMSs switching off at the same time.

Some batteries have communications built in, this is an elegant solution for paralleling lithium batteries correctly.Over temperature:

Over temperature (or under temperature although less common in Australia) damages lithium batteries. Over 60C is an absolute NO for lithium. This means no under bonnet use. Lithium batteries should be kept within their rated temperature limits.

Over Current:

If too much current is drawn from your lithium battery, exceeding the manufacturer specifications, you have likely permanently damaged your battery. Drawing too much current will damage the BMS. If the BMS happens to have over-current protection, removing the load may reset the BMS to allow it to continue working.

Troubleshooting | Prebuilt Batteries

When talking about prebuilt lithium batteries, we are referring to batteries that are premade by a manufacturer. They are commonly fully sealed with a BMS built in.

Drypower pre-built LiFePo4 battery Resetting a BMS:

If your BMS has tripped it will need to be reset:

- Remove the load or charger. The BMS may self reset after a few seconds

- Put a charger on the battery. It should reset the BMS and the battery should begin charging.

If these two methods don’t reset your BMS you can try the following options. These options can help reset even more troublesome BMSs:

Charge the battery with a Victron MPPT charger. Victron MPPT chargers begin to charge regardless of tripped BMSs. This can sometimes restart a stubborn tripped battery

You can momentarily connect the battery to a power supply of appropriate voltage (not recommended).

Balancing Cells:

If you suspect the cells within your battery are unbalanced, often evident through poor battery capacity, it is possible to help them balance. What you need to do is discharge the battery slowly using a fridge or small load (around 1-5A). Once the battery is discharged almost fully, slowly charge the battery (2-6A charge current). Repeating this process a few times can allow the battery balancer to work and bring the cells back into balance.

Troubleshooting | DIY Lithium Batteries

Common fixes for batteries built from lithium cells

Cell wiring inside an Off Grid Lithium Battery Box Incorrect Cell Wiring:

(very common)

Symptoms:

Balancer damage

BMS damage

Cell bulging/damage

Fix:

Ensure there are no loose connections

Make sure the sense wires are connected in the correct order and to the correct cell

Check that the sense wires are protected from strain and physical damage

Here you can see the sense wires are in the wrong order

Here you can see correctly ordered sense wires Incorrect cell wiring is a critical error. You must ensure that when building a DIY lithium battery you wire every sense wire to the BMS and balancer in the correct order and tighten them very securely. Sense wires need to be protected from strain and damage.

If you have incorrect cell wiring there is a good chance you have damaged your BMS and balancer. You may need to purchase replacements to get your battery working again.

Unbalanced cells:

Fix:

Attempt to encourage the cells to balance by discharging the pack using a light load and slowly charging the pack. This can help the balancer do its job more effectively.

Check your balancer is working correctly. Ensure that it does not appear damaged and that all the appropriate indicator lights come on. If you have a clamp meter, check to see if current is flowing while the battery is charging and almost full.

If the balancer is working and the cells are still going out of balance, it is possible that you have a weak cell. This cell needs to be identified and replaced. To test a cell you can perform a full rundown test (recommended) or monitor the cells and see which cell is causing the BMS to trip on both high and low voltages. The normal range for a cell voltage is between 2.5 to 3.65V. Cell voltages around or outside these values will cause a BMS to trip.

Tripped BMS:

If you have a tripped BMS on your DIY lithium kit you should first attempt to reset it in the same way as a prebuilt battery.

If you still cannot get the BMS to turn back on you may attempt to manually reset the BMS. With our range of OGL BMSs you can very briefly place a piece of wire between the B- and P- terminals of the BMS to manually reset it. NEVER leave this wire connected for longer periods of time. Ensure that there are no heavy loads running or big chargers charging while you do this.

Left BMS demonstrates burnt resistors- Right BMS a damaged terminal Damaged BMS:

Symptoms:

BMS not turning on despite all the cells being within the correct voltage range and attempts have been made to reset the BMS.

BMS getting extremely hot despite current draw being within its rated limits

Fix

It is unlikely that a BMS has failed for no reason. First find the cause of the failure whether that be incorrect installation, overheating, over-current, etc. Then replace the BMS.

Balancer shows signs of burning and capacitors which have exploded Damaged Balancer:

Symptoms:

Cells going out of balance

Balancer looks burnt or capacitors have come off

Fix:

Commonly the balancer fails because it was connected while the sense wires were installed on the cells. Having sense wires partially connected to the balancer, either while installing or due to loose connections, WILL damage the balancer. Once the cause of the balancer failure has been determined, replace the balancer.

Moisture:

Water and electronics do NOT mix. Water or humidity can easily damage the BMS or balancer.

Water and Lithium ABSOLUTELY do not mix. Lithium batteries should never get wet and should be placed in a dry, cool environment.

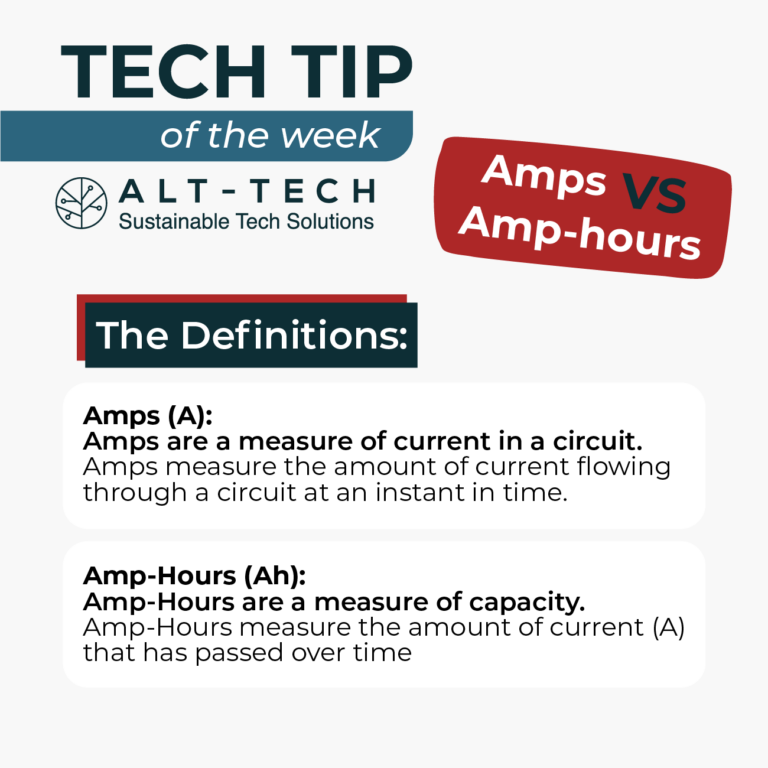

Amps VS Amp-hours

Understand the difference between amps and amp-hours and how they affect one another.

Simple Explanation:

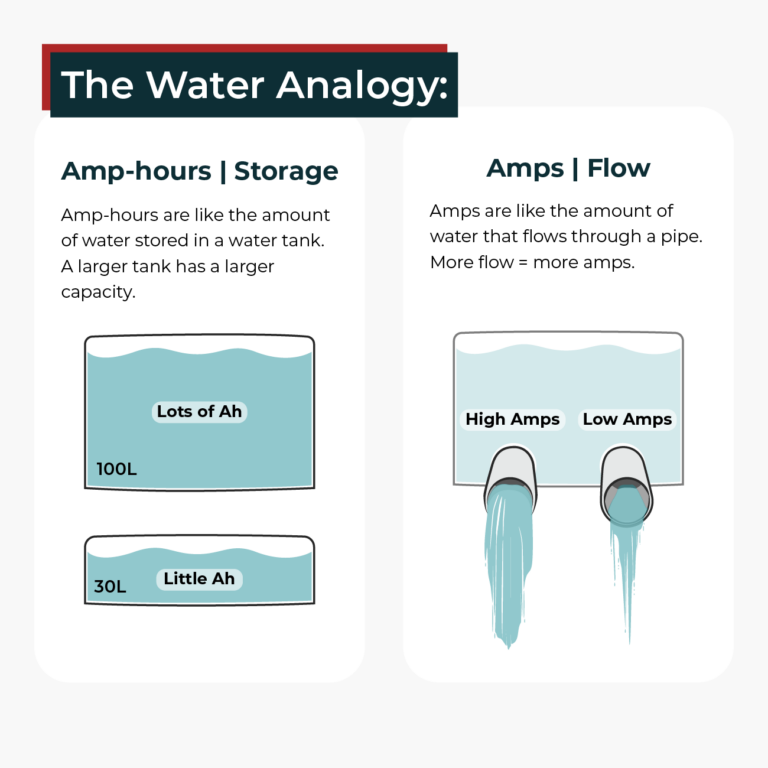

Amps (A):

Amps are like the amount of water that flows through a pipe. More flow = more amps.

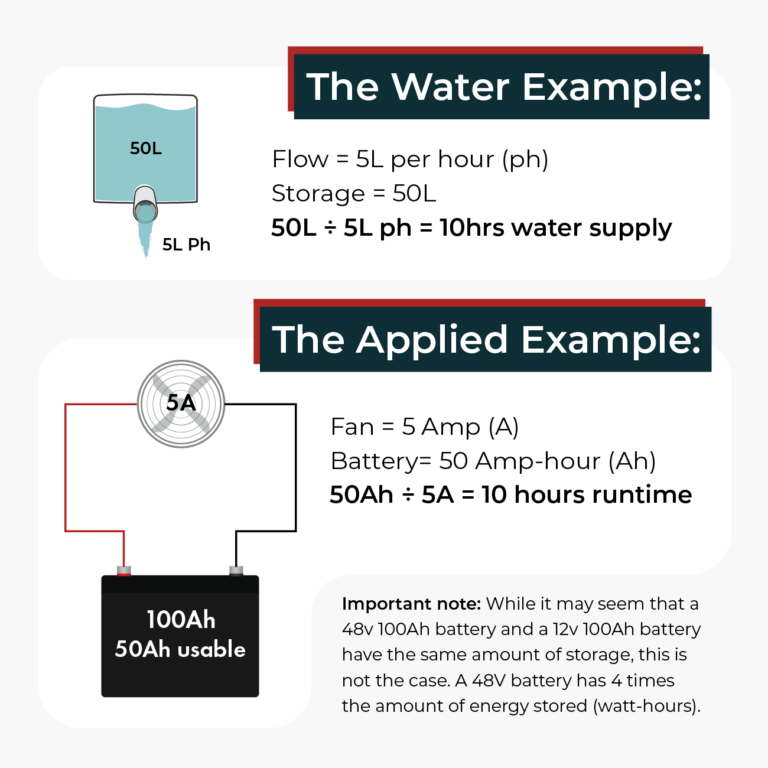

Example: Lets imagine a pipe with a flow of 1 Litre per hour.Amp-Hours (Ah):

Amp hours are like the amount of water stored in a water tank (Litres). A larger tank has a larger capacity.

Example: Lets assume you have a 50L tank (Similar to 50Ah). If you had a flow of 5L per hour (Lets call this 5A) the tank would empty in 10 hours.Electrical Explanation:

Amps (A):

Amps are a measure of current in a circuit. Amps measure the amount of current flowing through a circuit at an instant in time.Amp-Hours (Ah):

Amp-Hours are a measure of capacity. Amp-Hours measure the amount of current (A) that have passed over time.

Calculation: Amp-Hours = Current (Amps) x Time (Hours).

Example: You have a fridge drawing 5A for an hour, you would have used 5Ah of your batteries capacity.Important note: While it may seem that a 48v 100Ah battery and a 12v 100Ah battery have the same amount of storage, this is not the case. A 48V battery has 4 times the amount of energy stored (watt-hours). This will be explored in a future tech tip.

Disclaimer: Never over discharge your batteries! Make sure that you dont exceed the maximum depth of discharge of the battery.

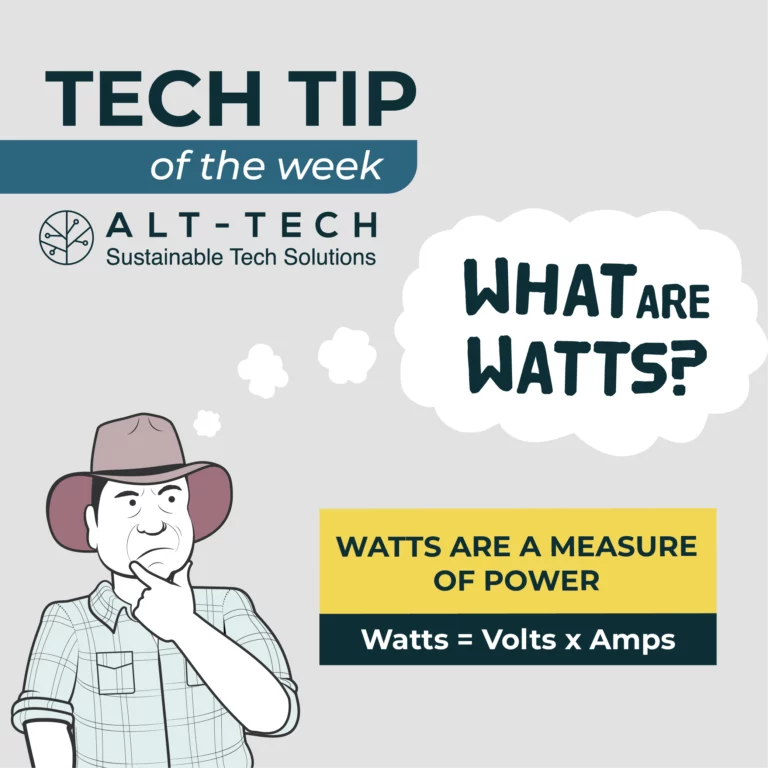

What are Watts?

Watts are a unit of power.

Power is defined as the instantaneous amount of energy delivered to a load. Watts should not be confused with watt-hours or kilowatt-hours. Watt hours are a measure of energy storage, which is a different topic to be covered in the future.

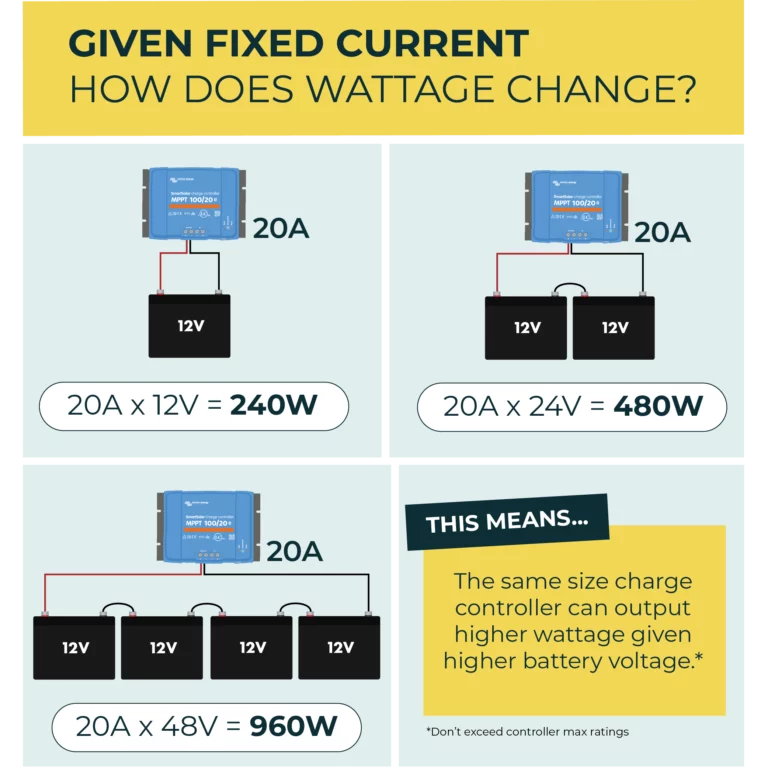

Power (Watts) = Volts (V) * Amps (A)

Lets consider a 10A draw from different battery voltages:

12V battery delivering 10A results in 120W of power.

24V battery delivering 10A results in 240W of power.

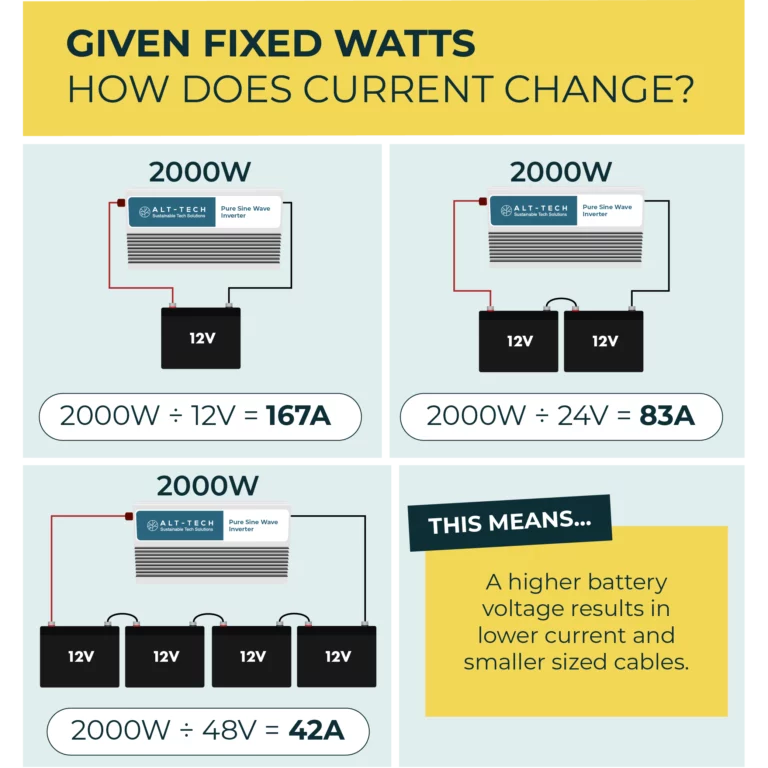

48V battery delivering 10A results in 480W of power.Lets now consider a 2000W load and different battery voltages:

2000W load on a 12V battery will result in a current draw of 167A.

2000W load on a 24V battery will result in a current draw of 83A.

2000W load on a 48V battery will result in a current draw of 42A.Sometimes running a higher battery voltages can have benefits.

– Being able to use smaller cables to run the same load

– Sometimes being able to use smaller devices to charge the same batteryIt is important to consider ALL factors when selecting a battery voltage. Higher voltage batteries are not always better, consider your use case and needs before deciding.

Disclaimer: ALWAYS remember to check your device’s specifications to ensure you don’t damage it by exceeding its capabilities.

Unveiling the Power of Lead-Carbon Technology Batteries: A Comprehensive Guide

Everyone knows about lead-acid batteries and most are aware of lithium, but if lead-carbon still has you scratching your head, this talk is for you. With growing efforts to move away from fossil fuels, creativity in the renewable energy & battery storage sphere has resulted in the melding of age old technology in innovative ways. The addition of carbon to familiar lead-acid battery technology has delivered a low-cost and sustainable new product to the consumer battery market.

If you really enjoy a deep dive into fine grain tech, you’ll love the ‘Construction of Lead-Carbon Batteries’ section, but if you prefer to keep it a bit more general, cruise on down to the ‘Benefits of Lead-Carbon Batteries’ section.

Understanding Lead-Carbon Batteries

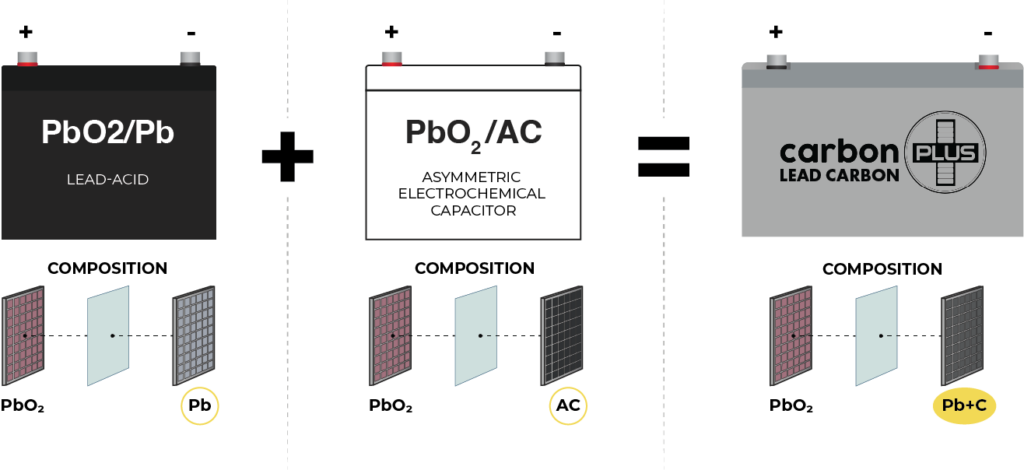

Lead-carbon batteries have gained prominence due to their ability to provide sustainable and cost-effective energy storage solutions. To achieve their benefits, lead-carbon batteries employ a hybrid design that combines traditional lead-acid components with high-surface-area carbon materials.

Construction of Lead-Carbon Batteries

Fig.1. Lead-carbon battery configuration. Adapted from [1]

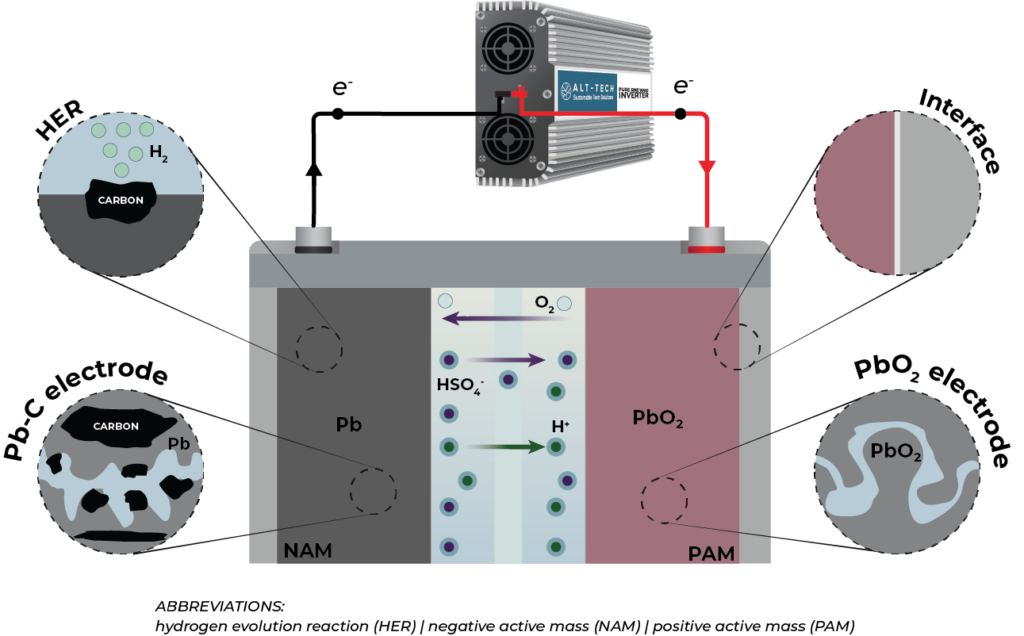

The construction of lead-carbon batteries involves modifying current LAB (Lead-Acid Battery) technology. The incorporation of activated carbon (AC) into the negative electrode enhances charge power and transforms the lead-acid battery into a lead-carbon battery. Lead-carbon electrodes, often referred to as LCBs, consist of a carbon-enhanced bifunctional lead-carbon composite negative electrode.

Key components inside a lead-carbon battery include sponge lead dendrites and AC particles connected in the negative active mass (NAM). This intricate structure enhances power and cycle life under partial state of charge (PSoC) operation. The addition of functional carbon materials addresses sulfation issues by increasing the conductivity of negative plates and providing additional active surfaces for lead sulfate (PbSO4) particles.

The inner structure of lead-carbon negative electrodes resembles a micro-ultrabattery negative plate, addressing challenges like parasitic hydrogen evolution reaction (HER), self-discharge, and electrode expansion during charge-discharge processes. Various carbon materials, such as carbon black, carbon nanotubes, graphene, and carbon nanofibers, are used as additives to enhance charge acceptance. The utilization of AC, known for its high specific capacitance, contributes to enhanced charge acceptance, even though it does not directly contribute to the capacitance of the lead-carbon electrode.

To counteract issues like parasitic HER induced by the exposure of carbon in the microstructure of lead-carbon to electrolytes, HER inhibitors (e.g., Zn, Ga, Bi, In, and Pb) are employed. A high affinity between lead and carbon components is essential for establishing a robust lead-carbon binary composite electrode. Despite the seemingly simple components, the lead-carbon composite electrode proves to be a sophisticated structure, requiring extensive research and design efforts for renewable energy storage and HEVs.

In the next section, we will delve into the mechanistic study and technological advancements of lead-carbon electrodes. Additionally, large-scale synthesis strategies of lead-carbon composite additives with potential applications in the NAM of commercial LCBs will be explored.

Fig.2. The main obstacles and considerations in lead-carbon batteries. Adapted from [1]

Benefits of Lead-Carbon Batteries

Extended Cycle Life: Lead-carbon batteries offer a significantly longer cycle life compared to traditional lead-acid batteries, incredibly close to nowadays lithium batteries really, making them a cost-effective solution in the long run.

High Charge and Discharge Rates: The incorporation of carbon materials enhances the power density of lead-carbon batteries, allowing for efficient charge and discharge operations, even under high load conditions.

Improved Performance at Low Temperatures: Lead-carbon batteries exhibit a broader operational temperature range compared to standard lead-acid and lithium LFP batteries. This versatility allows lead-carbon batteries to function in a variety of environmental conditions, making them suitable for applications with a wider temperature range.

Enhanced Efficiency and Energy Density: The hybrid design of lead-carbon batteries results in improved efficiency and energy density, contributing to their widespread adoption in renewable energy storage systems.

Electronics-Free Design: A significant advantage of lead-carbon batteries is their simplicity. Unlike modern lithium batteries that often include complex electronic components, lead-carbon batteries maintain a simple design. The lack of electronics decreases the number of things that can fail and increases reliability.

Cost-Effective Energy Storage: Lead-carbon batteries provide a great price per kilowatt-hour (kWh) of usable energy when accounting for both initial cost and expected longevity. This cost-effectiveness makes them a compelling choice for applications where optimizing the balance between performance and budget is crucial.

Environmentally Friendly: With a focus on sustainability and a recycling rate of 97%, lead-carbon batteries stand out as an environmentally friendly option, particularly when compared to the unresolved recycling challenges associated with lithium batteries.

Drawbacks of Lead-Carbon Batteries

Limited Energy Density Compared to Lithium-Ion: While lead-carbon batteries offer enhanced energy density compared to traditional lead-acid batteries, they still lag behind lithium-ion batteries in terms of energy storage capacity by size and weight.

Comparison with Lithium Iron-Phosphate Batteries

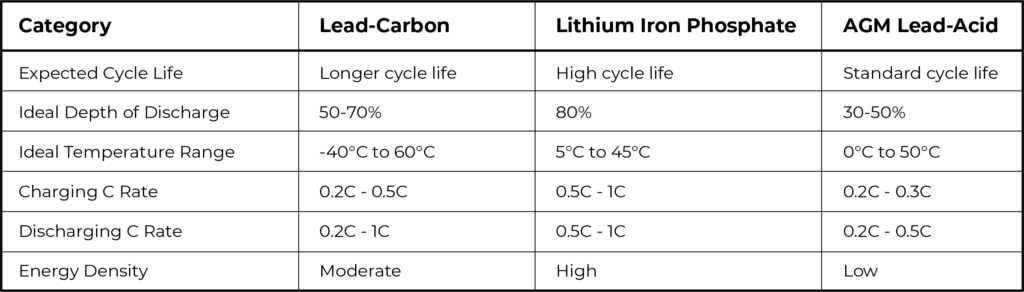

Now, let’s compare lead-carbon batteries, specifically the AGM type, with lithium iron-phosphate (LiFePO4) batteries, focusing on key parameters:

When to Choose Lead-Carbon

In the rapidly evolving landscape of energy storage solutions, lead-carbon batteries (LCBs) have emerged as a formidable option, especially in stationary applications where reliability and longevity are paramount. Their extended cycle life, high charge-discharge rates, and improved performance in ranging temperatures make them a cost-effective and sustainable choice for various energy storage needs.

On the other hand, lithium iron-phosphate (LiFePO4) batteries excel in portable applications where temperature control and space constraints are critical considerations. The high energy density and compact design of LiFePO4 batteries make them ideal for powering portable electronic devices and electric vehicles, providing efficient and reliable performance in situations where size and weight matter.

Ultimately, the choice between lead-carbon and lithium iron-phosphate batteries depends on specific application requirements. Lead-carbon batteries shine in stationary setups, offering robustness and reliability, especially in higher temperature environments. Meanwhile, lithium iron-phosphate batteries carve a niche in portable and space-restricted scenarios, delivering compact and temperature-controlled power solutions. As technology advances, these two technologies will likely continue to complement each other, catering to diverse energy storage needs across different sectors.

Lead-Carbon Batteries

If you’re considering lead-carbon batteries for your system, we have a range of carbonPLUS 2V and 12V batteries available. Each product has a specification sheet if you need to delve into finer details.

carbonPLUS Range

References

[1] Yin, J. Lin, H. Shi, J. et al. Lead‑Carbon Batteries toward Future Energy Storage: From Mechanism and Materials to Applications. Electrochem. Energy Rev. 5, 2 (2022). https://doi.org/10.1007/s41918-022-00134-w